Connectors

Tags: Installeren

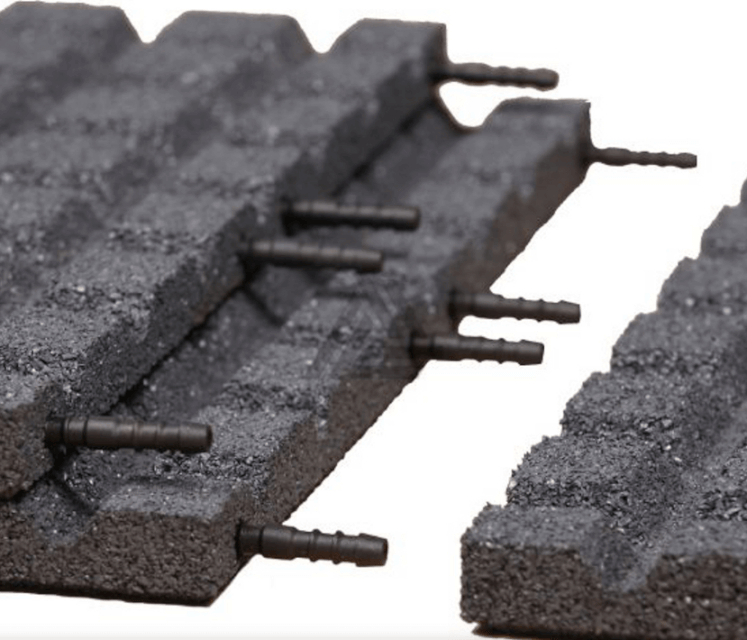

Rubber tiles are supplied with a pin-and-hole connection system, allowing the tiles to be effortlessly linked together. Each rubber tile features four holes on two sides. These four holes serve as anchoring points for the plastic connecting pins. Using these pins is essential when installing a rubber floor. The connecting pins create a stable surface and ensure that the rubber tiles remain in place, forming a firm and safe flooring system. For the most stable layout, the rubber tiles should be installed in a half-brick pattern.

The connecting pins can be supplied in various ways.

They can be packaged in bulk per bag, allowing installers to immediately start installing the rubber tiles. An alternative option is to pack the pins in sets of 24, for example, in a (customized) pouch. This makes them suitable for inclusion with rubber tiles sold in DIY stores and garden centers.

An additional option is to pre-attach the pins directly to the underside of the rubber tile. This way, the pins are delivered together with the tiles, enabling the end user to get started immediately without needing to purchase the pins separately.

Advantages of connecting pins:

-

Stable positioning: Connecting pins provide a solid link between the tiles, preventing them from shifting or coming loose, even under heavy use. This is particularly beneficial in high-traffic areas such as gyms, playgrounds, and public spaces.

-

Easy installation: The connecting pins for rubber tiles are easy to use and do not require complex installation. They can simply be inserted into the pre-formed holes in the tiles, where they fit securely to create a strong connection.

-

Safety: Secure connections between rubber tiles are crucial to prevent tripping hazards. The connecting pins hold the tiles tightly together, creating a flat and even surface. This minimizes the risk of uneven edges between tiles.

-

Removable: In the event of damage to a rubber tile, it is easy to remove and replace the damaged tile with a new one.